Heatsinking is always a good idea, but the goal was to create small LED lights that needed nothing more than a power source.

A heatsink is needed to dissipate the heat, moving it away from the LED to avoid permanent damage. LEDs typically have a good amount of power flowing through a very small source, allowing heat to build up. Heatsinking LEDs is another area that is confusing as you start to work with LED lighting.

Diy mini led panel driver#

Takes away the stress of matching up a driver with your LED circuit.

Diy mini led panel drivers#

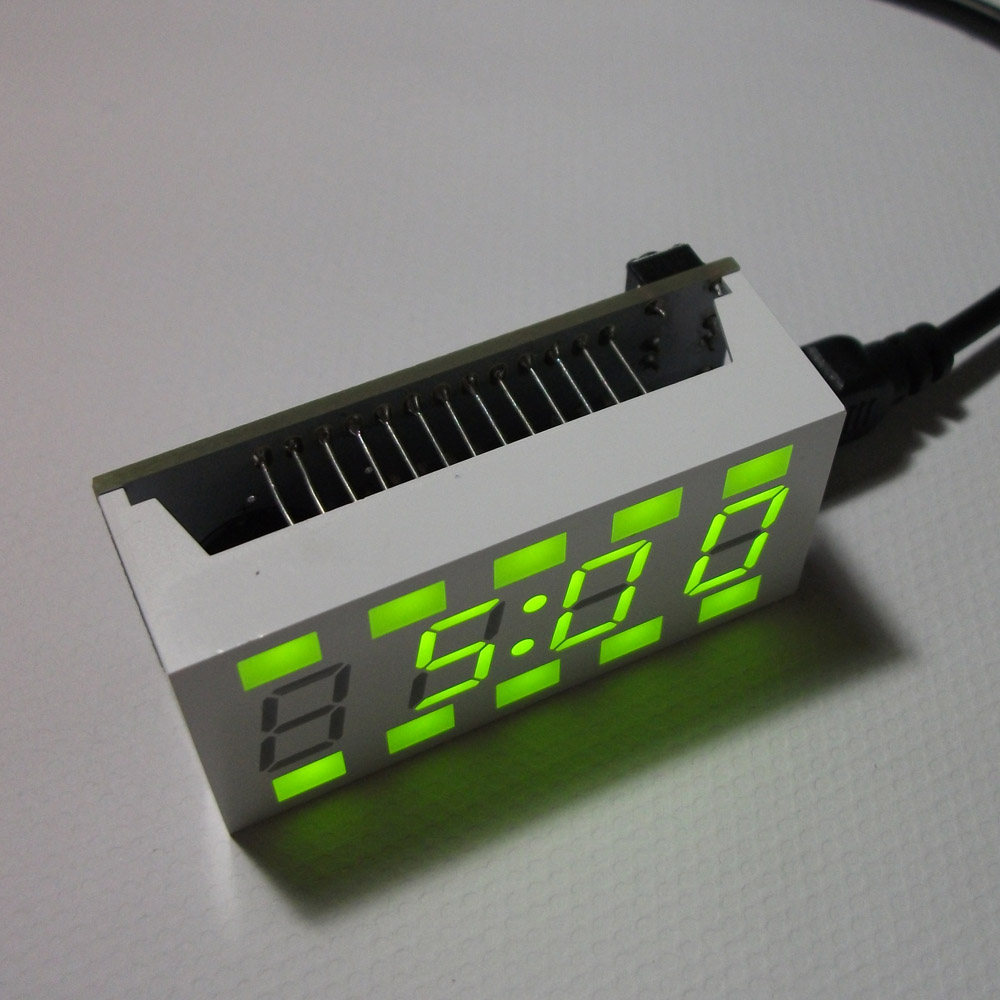

On-board drivers are much smaller, making for a more compact and discrete setup.On-board drivers mean no need for an external driver that can cost around $10-$15.These small drivers act as variable resistors on the board so that you can input a constant DC voltage (such as 12 volts) and the devices will limit the current allowed to flow through the board. Instead of using an external driver, the goal was to build small on-board drivers onto the LED board. LED lights electrical properties change as they heat up, a driver will make sure the LED stays at a safe current instead of drawing too much and ultimately burning out. When working with SMD LED lights, a constant current driver or current limiting resistor is needed. In our collaboration, there were 4 major features that I wanted our new products to have. I started collaborating with LuxDrive to create an LED light that would work in this way. LED flex strips are great for use like this, but sometimes a more compact, direct and high quality light is needed. Designing All-in-One LED LightsĪfter fielding many calls and inquiries here at LEDSupply, I realized we needed more LED light engines that could take a constant 12-24VDC input and light up. Sound too good to be true? Come look at how we designed these LED lights. This eliminates the barriers to entry for people, just like you, who want to design an LED light system without getting in over their heads. Our LED light engines are designed to take the list of components above and combine them into a single package. A light engine usually consists of a light emitting diode (LED) mounted on a circuit board that has electrical and mechanical fixings, meaning it is ready to be fixed in the luminaire. What is an LED light engine? It is the LED equivalent of a conventional lamp. LED light engines only need a power source and a bit of imagination to create LED lights for both small and large applications. Before tossing the project in the ‘Save for Later/Someone Else’ pile, you should know there is a way around using all these components for one simple light. This list can understandably confuse a newcomer and make that cool lighting project seem like a headache. Surface mount device (SMD) LEDs or LED Modules.This would start a discussion about the different components needed to complete an LED setup: With the growing popularity of LED lighting, many have researched and contacted me asking how to create small LED lights, LED lamps, LED panel lights, downlights…you name it. Ever wanted to build an LED lamp? Now you can with just 2 parts!

0 kommentar(er)

0 kommentar(er)